The principle of operation for a tablet

2024-12-28 15:29

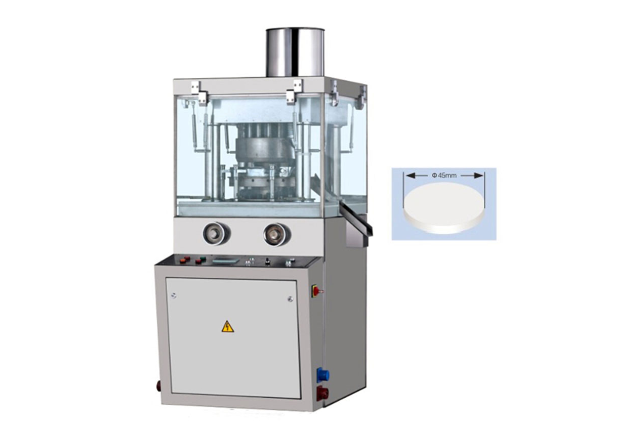

The principle of operation for a tablet press can be explained as follows:

1. Dose Control: Different tablets necessitate varying doses. For larger quantities, different-sized punches with diameters such as 6mm, 8mm, 11.5mm, and 12mm are employed. After selecting the mold size, finer adjustments for smaller doses involve altering the depth at which the lower punch enters the middle cavity, altering its actual length after compression and thus affecting drug filling. A mechanism for adjusting the initial position of the lower punch is crucial in meeting dose control needs, especially considering variations in powder bulk density among batches.

2. Thickness and Compaction Control: The dosage is fixed based on prescriptions and pharmacopoeial standards. The pressure applied during compression, which impacts storage stability and dissolution times, determines the final thickness and appearance of the tablets. This pressure regulation is achieved by adjusting the downward travel of the punches in the die holes. Some presses incorporate not only linear up-and-down motion but may also employ more advanced features to control compaction during the process.

In summary, a tablet press combines precise dose and thickness management through adjustable punch mechanisms, while maintaining consistency across batches and ensuring optimal product quality according to pharmaceutical specifications.

Get the latest price? We'll respond as soon as possible(within 12 hours)