Laundry Detergent Tablet Press Machine

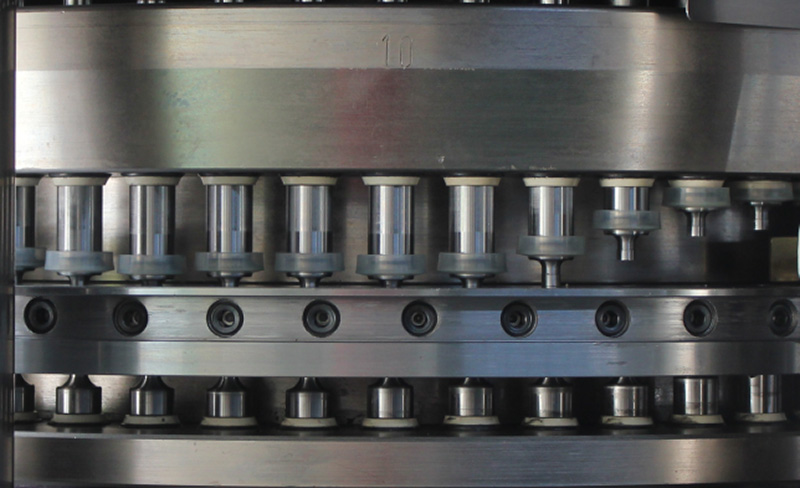

1. The frequency conversion motor is used for speed regulation, and the worm gear is driven by the synchronous pulley to make the turntable rotate. The rotation of the turntable drives the 45 dies to run clockwise. Each pair of punching dies is composed of feeding, filling, tablet pressing and tablet pressing processes through the upper and lower guide rails and pressing wheels.

2. The pressure, filling, sheet thickness and rotational speed of the machine can be adjusted. All adjustment hand wheels are on the front of the machine, and there are instructions on the operation panel. Simple operation and convenient maintenance.

- lvyi

- Shanghai, China

- 30 days after advance payment

- 120 sets per year

Details

1. Laundry Detergent Tablet Press Machine

2. Main Pictures

3. FEATURES

This machine is suitable for the pressing of granular raw materials whose powder content (above 100 mesh) does not exceed 10%. This machine is not suitable for the compaction of semi-solid, moist granules, low melting point, moisture-prone raw materials and non-granular powders.

4. SPECIFICATIONS

Product No. | ZPT420-19D |

Quantity of Punch & Die (set) | 19 |

Max. Pressure (kn) | 160 |

Max. Dia. of Tablet (mm) | 40 |

Max. Thickness of Tablet (mm) | 12 |

Max. Depth of Filling (mm) | 20 |

Rotate Speed (r/min) | 20 |

Production Capacity (pc/h) | 30000 |

Motor Power (kw) | 7.5 |

Overall Size (mm) | 1240×980×1650 |

Weight (kg) | 1950 |

5. RANGE OF CONFIGURATION

This machine is a machine with automatic rotation, frequency conversion and speed regulation, and continuous tablet pressing. It is mainly used for tablet manufacturing in the pharmaceutical industry, and is also suitable for compressing granular raw materials into tablets in chemical, food, electronics and other industrial sectors.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)