Disinfection Alcohol Tablet Compression Machine

(1) The upper pressing wheel is provided with an unloading device, and its pressure can be adjusted.

(2) When the working pressure of the punch exceeds the preset pressure, the unloading is unloaded by the compression of the spring, and the machine stops immediately to prevent damage to the parts.

- lvyi

- Shanghai, China

- 30 days after advance payment

- 120 sets per year

Details

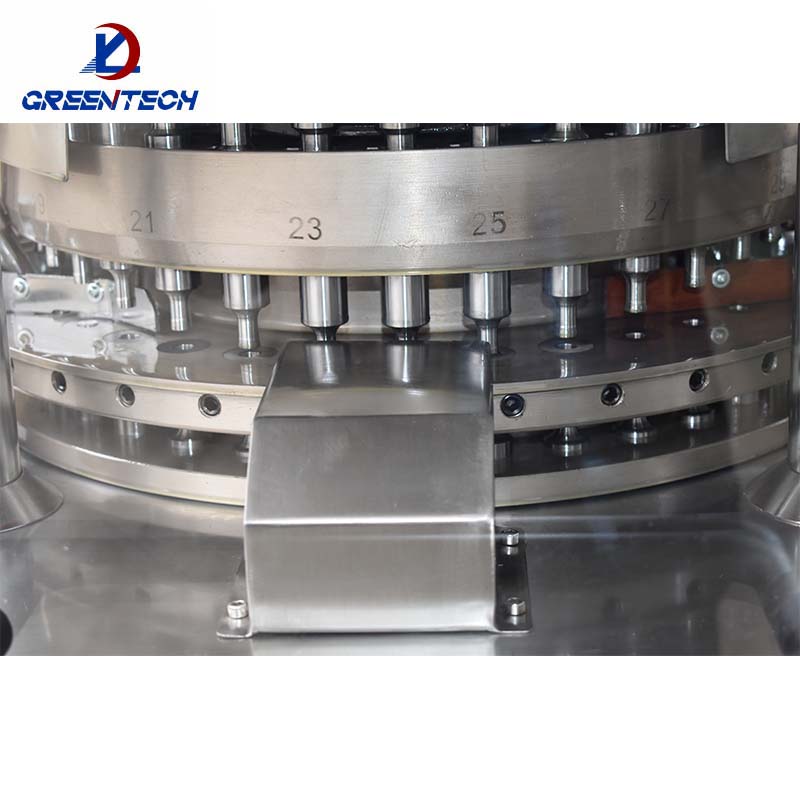

1. Disinfection Alcohol Tablet Compression Machine

2. Main Pictures

3. FEATURES

(1) The upper part of the tablet press is a completely sealed tableting chamber, which is the part that completes the entire tableting process.

(2) It includes a feeding system, a punching combination, a tablet ejecting device, and a dust collection system.

(3) The tableting chamber consists of a top plate, a cover plate and a plexiglass door.

(4) The tableting chamber is completely sealed by a sealing strip to prevent external contamination of the tableting process.

4. SPECIFICATIONS

Model | ZP420-45D |

No.of Stations | 45 |

Max Production Capacity(pcs/h) | 162000 |

Max Turret Speed(r/min) | 0-30 |

Max Pressure(kn) | 100 |

Max Filling Depth(mm) | 15 |

Max Tablet Thickness(mm) | 0.5~6 |

Max Tablet Diameter(mm) | Ф11 |

Motor Power(kw) | 4KW/380V,50Hz,Three-phase five-wire system |

Overall Size(mm) | 1240*850*1850 |

Machine Weight(kg) | 1750 |

5. PRODUCT DESCRIPTION

(1) The material used in this machine is selected in strict accordance with GMP requirements.

(2) The surfaces of the moving parts in the tableting chamber of the equipment are not painted or electroplated.

(3) The parts in contact with medicines such as the middle punching plate, the feeder chassis, the operating surface, the filming guide groove, the cabinet, The protective door panels are made of stainless steel.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)