Energy-saving Camphor Pills Compression Machine

(1)The machine adopts closed oil-immersed lubricated worm gear transmission, which prolongs the service life of the worm gear and worm transmission.

(2)The upper guide rail, transmission worm, feeding hopper, feeder, filling rail and other spare parts of this machine are all common with ZP17 tablet press. The punching die of this machine conforms to the standard "JB20022-2004", and is common to the ZP17 tablet press.

- lvyi

- Shanghai, China

- 30 days after advance payment

- 1000 Set/Sets per year

Details

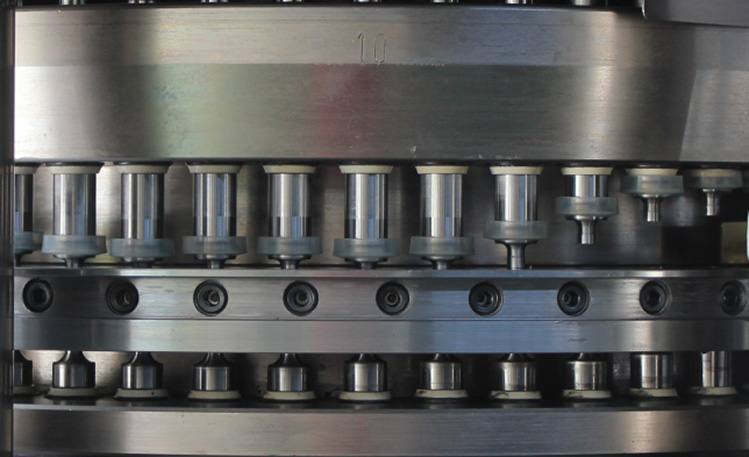

1. Energy-saving Camphor Pills Compression Machine

2. Main Pictures

3. SPECIFICATION

Model Parameter | ZPT420-45D |

Punch pin number | 45 |

Punch diameter | 19mm |

Die diameter | 22mm |

Production range (10,000 tablets/h) | 162000 |

Rotating speed (rmp) | 0-30 |

Maximum pressure | 100KN |

Maximum filling depth | 15mm |

Tablet thickness | 0.5~6mm |

Maximum tablet diameter | Ф11mm |

Maximum abnormal axis size | <18mm |

Punch length | 133.6mm |

Working noise | ≤70dB |

Total power | 5.5KW/380V,50Hz,three-phase five-wire system |

Bounday dimension of equipment | 1240*850*1850 mm |

Net weight of equipment | 1750kg |

Remark | The maximum production refers to the maximum production realized under the conditions of round tablets, minimum tablet diameter and maximum rotating speed. The production is influenced by tablet diameter and tablet type. |

4. PRODUCT DESCRIPTION

(1) The drive mechanism of the tablet press is completely isolated from the compression chamber to ensure that the tablet meets GMP requirements.

(2) Non-toxic, non-corrosive stainless steel plates are used to isolate it from other parts in the tablet compression chamber.

(3) There are sealing devices all around to prevent cross contamination with the outside world.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)